The leading broaching machine manufacturers both domestic and international.GLOBAL COMPANY

The company has professionals with 20~30 years of experience with manufacturing of the broaching machine, and so the company can be active both domestically and internationally.

Research Field

ATC (Automatic Tool Changer) : Broaching Tool

Auto Tool Changer

-

- Purpose

- Smartification to improve machine tool productivity and operating rate

-

- Contents

- Contributing to small quantity production of multiple products, optimizing processing conditions, reducing production costs, meeting user needs

-

- Core Technology

-

- Broaching tool calling technology, according to the change of the target product during cutting.

- Technology that quickly picks up and exchanges various types of broaching tools.

ATC(Automatic Tool Changer) Technology in the Broaching Machine

ATC Application Broach Range

-

- Tool Weight

- Less than 500 kg(Including the Broach Holder)

-

- Tool Diameter

- PI less than 150 mm

-

- Tool Length

- Less than 1200 mm (Broach Holder Excluded)

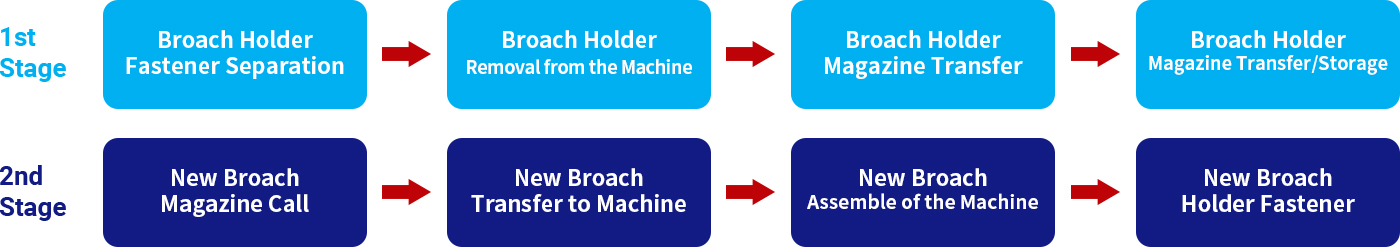

Tool Change Process

-

- ATC Type

- Magazine Type(Tool Storage Quantity : 6 EA)

-

- Tool Storage Method

- Sequence / Random Method

-

- Machine and Tool Holder Fastening Method

- SLEEVE & CLAW Type

-

- Tool Transfer Method(Between Machine and Magazine)

- Electric Motor / Pneumatic Finger (Considering Tool Weight)

-

- Tool to tool Time

- Within 3 minutes (1/60 Work Speed Compared to Manual Work)

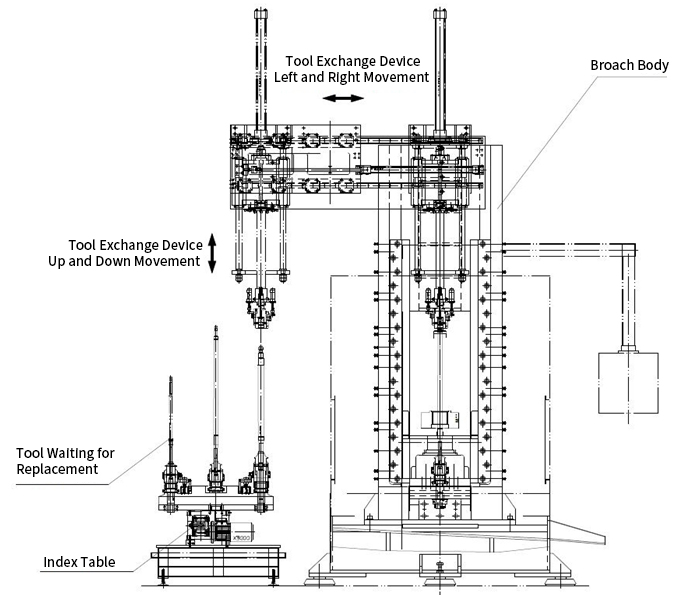

ATC : Schematic Diagram of Development

Auto Tool Changer

ENG

ENG