The leading broaching machine manufacturers both domestic and international.GLOBAL COMPANY

The company has professionals with 20~30 years of experience with manufacturing of the broaching machine, and so the company can be active both domestically and internationally.

Research Field

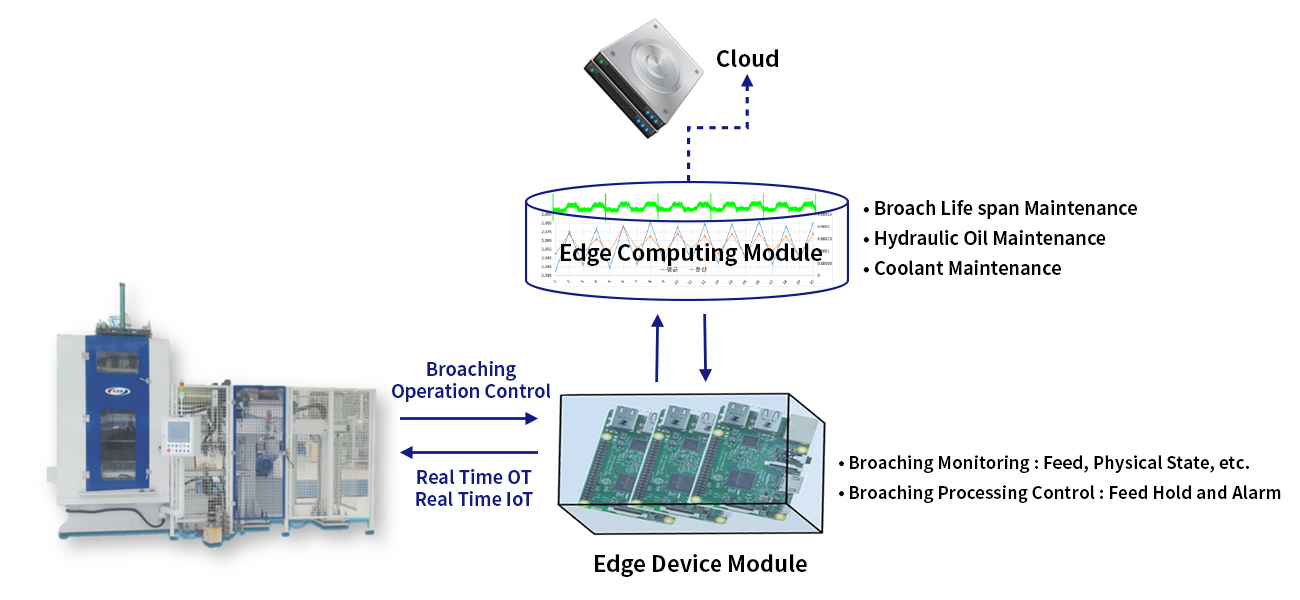

Smart Edge

Smart Edge Concept

-

- Purpose

- Making the system smart to increase machine tool operation rate and productivity

-

- Contents

- Optimization of machine conditions, DB of mechanical history, information for machine predictive maintenance.

-

- Core Technology

-

- Required A/S and B/S Function

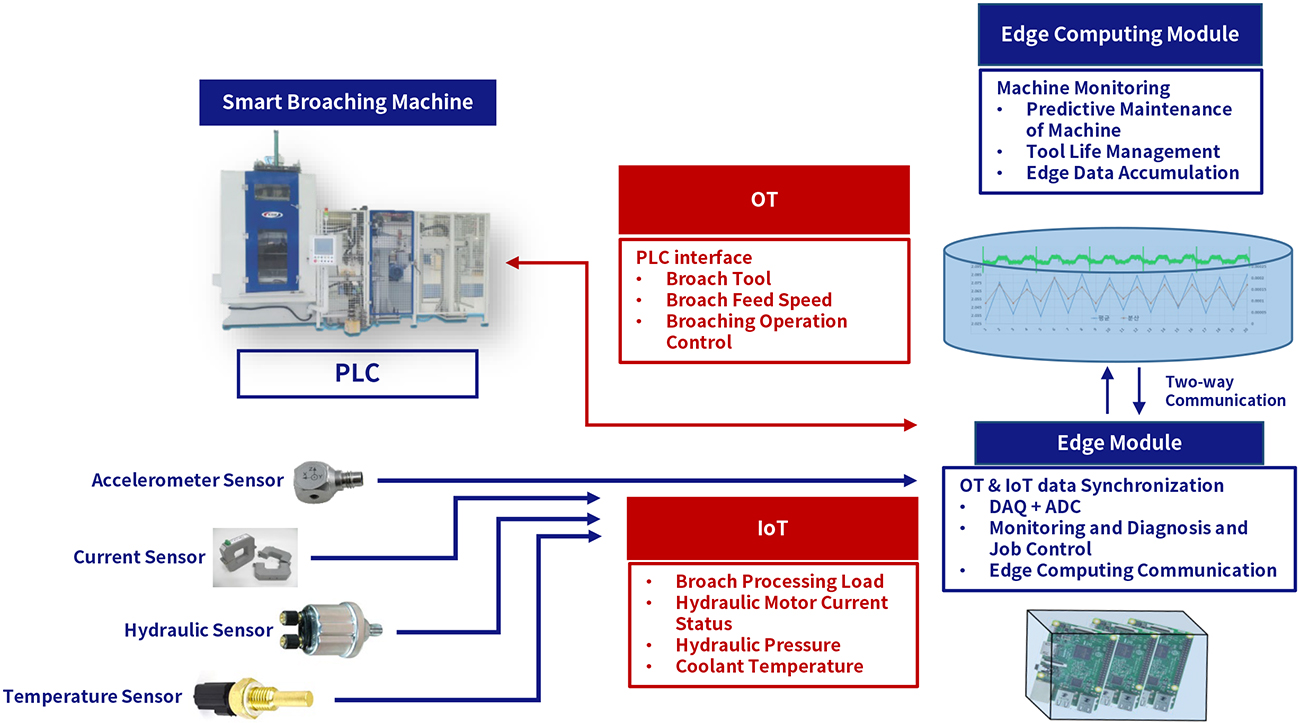

- Real-time interface technology with the controller and PLC

- Monitoring, analysis, and diagnosis technology of various sensing data.

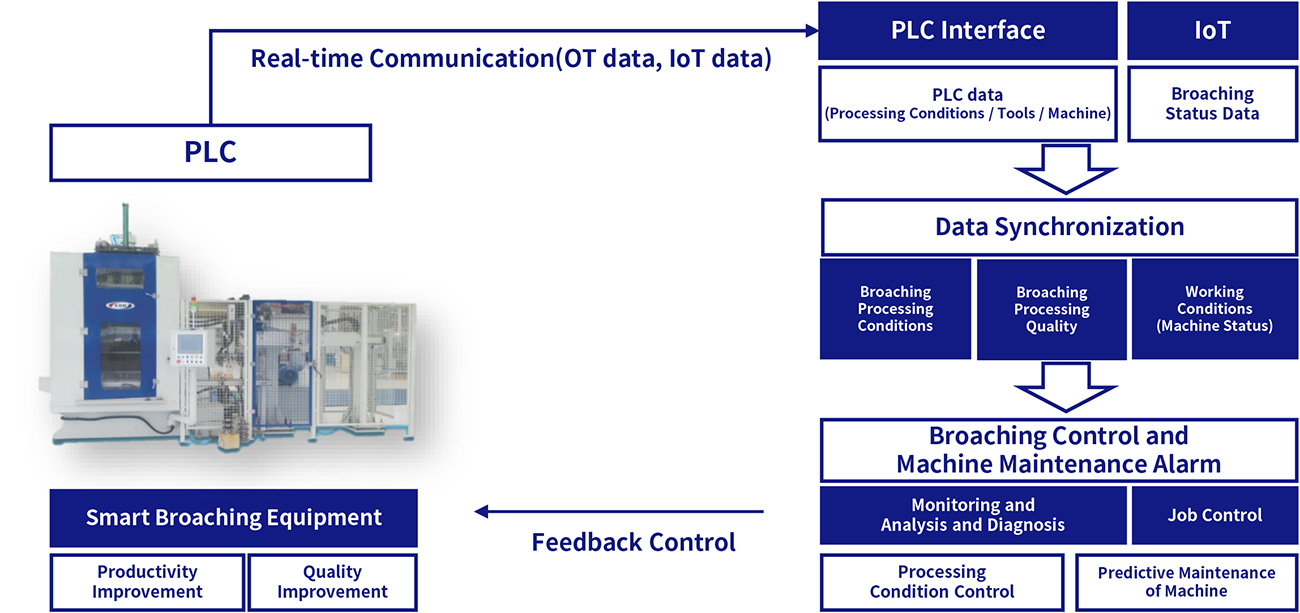

Broaching Machine Smart Configuration Technology

Edge Device

-

- Important Function

- Real-time monitoring and control of working conditions and status.

-

- Implemented Technology

- Real-time two-way communication interface implementation technology with the mechanical tools.

Edge Computing

-

- Important Function

- Maintenance through the monitoring of data analysis.

-

- Implemented Technology

- Synchronization of work conditions and real-time work status and control to normal status after correlation analysis.

Technical Elements for Monitoring and Controlling Broaching Conditions

Monitoring Synchronization

-

- Monitoring Target

- Broach(Tool), Hydraulic Oil and Hydraulic System, Cutting Oil, etc.

-

- Monitoring Items

- Broaching Feed Rate, Machining Vibration, Cutting Oil Temperature, Hydraulic Oil Condition

-

- Synchronization of Monitoring Data

- Control of broaching work and predictive maintenance alarm through monitoring data analysis and diagnosis.

ENG

ENG